Xihoumen Road-Railway Bridge

Stayed less than half a year

Be the first to complete the task of drilling eight 6.3-meter large-diameter main piers

Construction efficiency is far ahead!

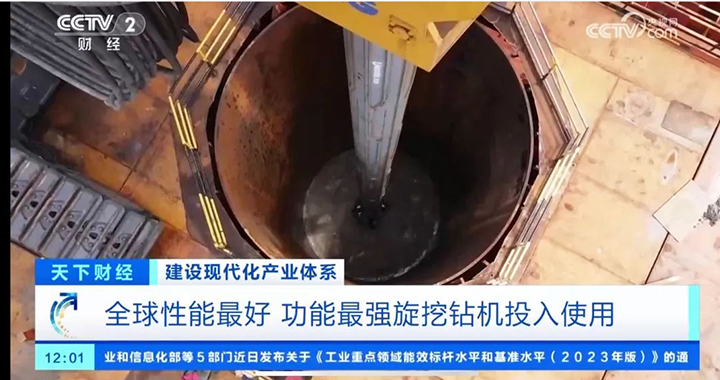

The main pier foundation of the bridge uses a total of 18 6.3-meter super-large diameter bored piles, which is currently the largest diameter bored pile foundation in China. The piles are 106 meters deep, the water depth is 66 meters, and they penetrate 40 meters into the rock. Some pile foundations are as deep as 116 meters. The XCMG XR1600E rotary drilling rig needs to pass through complex formations such as highly weathered granite, weakly weathered crushed granite, cataclastic rock, slightly weathered crushed rhyolite, and lay the foundation for the bridge deep under the sea.

Rock drilled by XR1600E rotary drilling rig

The construction platform where the XCMG XR1600E rotary drilling rig is located has relatively hard ground, and the seafloor stratum is inclined rock. The project team used a hob-type drill bit to expand the hole in four stages to ensure the verticality of the pile foundation. It broke the conventional graded hole expansion process and reduced the number of classifications. It took the lead in adopting the four-stage hole expansion process of 2 meters, 3 meters, 4.5 meters, and 6.3 meters, breaking through the 1.8-meter step difference in graded hole expansion.

XCMG's XR1600E rotary drilling rig completes one pile in an average of 10 days. It is almost fully on duty and completes the project department's 8 pile construction tasks with high quality. This is a challenge between machines and nature, and it is also a battleground for equipment in the same industry. According to on-site construction data feedback, XCMG equipment efficiency is nearly 15% ahead, and it is the first to complete the tasks assigned by the project department.